Specialised Wool Equipment

Wool ComfortMeter

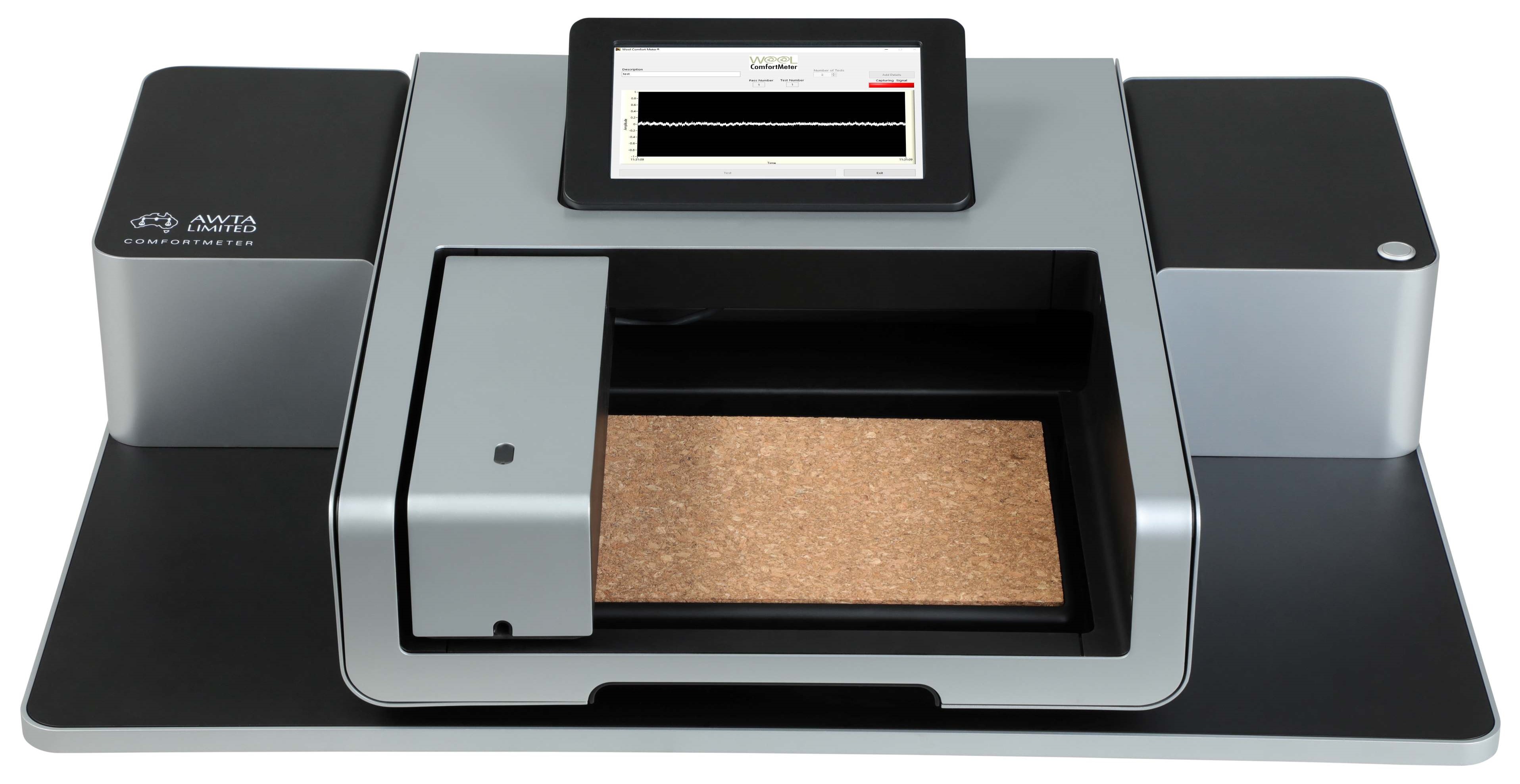

Retailers and manufacturers now have a reliable means of objectively specifying and promoting a garment on the basis of superior comfort for the wearer, using The Wool ComfortMeter; a easy-to-use desktop instrument.

Accurately and easily measure fabrics for next-to-skin comfort values.

Retailers and manufacturers now have a reliable means of objectively specifying and promoting a garment on the basis of superior comfort for the wearer.

The Wool ComfortMeter is an easy-to-use desktop instrument, which provides accurate objective measurements of fibre-ends in fabrics, which could irritate skin nerve endings, resulting in wearer discomfort.

What is textile comfort?

Textile fibre-ends which are fine enough to not push against the wearer’s skin, results in a soft, comfortable feel. However, if coarser fibres are present, the ends can irritate skin nerve endings, making it feel scratchy or itchy.

The good news is that there is now a reliable, objective way to assess fabrics for the fibre-ends which could cause discomfort.

Wool ComfortMeter - How does it work?

The Wool ComfortMeter analyses a fabric surface for presence of fibres known to cause prickle. The instrument calibrated was developed using extensive consumer wearer trials, where samples are assigned a single numerical score; the lower the score the higher the consumer comfort. A higher score means that the fabric risks some irritation to the skin.

A higher score means the fabric risks some irritation to the skin

A higher score means the fabric risks some irritation to the skin

If the fabric tested is intended for fashion wear under everyday conditions, a slightly higher score is acceptable (Column 1). If the intended end use is active wear, or performance is required under more extreme conditions, then a lower score will be required (Column 2). This is because when skin becomes wet and temperature is raised it becomes more sensitive.

| 1 - EVERYDAY FASHIONS |

2 - ACTIVE WEAR | |

| % of consumer acceptance for comfort level |

Comfort level Wool ComfortMeter |

Comfort level Wool ComfortMeter |

| 90 | < 450 | < 250 |

| 80 | 450 - 510 | 250 - 320 |

| 70 | 510 - 600 | 320 - 400 |

| 60 | 600 - 660 | 400 - 480 |

| 50 | 660 - 730 | 480 - 550 |

| 40 | 730 - 810 | 550 - 620 |

The quest for comfort

The Wool ComfortMeter can be used by a retailer to test existing products or as part of their innovation and development process.

A retailer simply specifies their preferred Wool ComfortMeter score to its supply chain partners. The supply chain is able to produce the products to the Wool ComfortMeter specification via wool sourcing, processing and fabric finishing techniques.

Retailers can monitor the consistency of the garment’s comfort quality by testing batch samples and compare against the acceptable Wool ComfortMeter score thus ensuring consistent quality between shipments and even from one season to the next.

Latest Video

Download Content

| LINK TO TECHNICAL MATERIAL Wool ComfortMeter |

|

Fleece Measurement Scour

How does it work?

The Fleece Measurement Scour SAFS1820 is specifically designed for scouring fleece wool samples extracted from the midside of sheep, weighing between 18 and 22 grams. Capable of processing up to 18 samples per wash, the scouring process effectively eliminates impurities such as dirt, suint (sweat salts), and grease. Notably, the scouring process does not entirely remove most vegetable matter, allowing for the determination of both Wool Base and Vegetable Matter base from the sample.

This efficient machine manages both the washing and rinsing of wool samples, requiring only one operator for loading and unloading. It features eighteen perforated sample bowls, each equipped with a specially designed agitator and a sample sieve. Additionally, a single spray gun with a flexible connection is included for rinsing the bowls after a cycle. The system incorporates a built-in detergent and antifoam agitation and injection system, seamlessly adding detergent to the hot water cycle.

Once the process is complete, the scoured wool sample is removed from the Fleece Measurement Scour SAFS1820, stacked with the Centrifuge Adaptor, and then spun in the Centrifuge 1500C or an equivalent machine to eliminate excess water.

Centrifuge Adapator

A specialised adaptor has been designed and can be optioned to seamlessly integrate with the Fleece Measurement Scour sample sieves and the AWTA Centrifuge 1500C. This guarantees the efficient removal of any excess water before the drying process, eliminating the necessity for modifications to the centrifuge.

User Interface

The Human Machine Interface (HMI) add-on touch screen enables users to interact with the Fleece Measurement Scour, allowing them to execute various test methods and procedures as needed. The HMI can also be configured to support multiple languages as an option.

Latest Video

Download Content

| LINK TO TECHNICAL MATERIAL Fleece Measurement Scour |

|