Yield & Fibre Diameter

AWTA Raw Wool's key service is the independent sampling, testing and certifying of the Yield and Fibre Diameter of greasy wool before it is sold. Prior to the measurment of Yield and Fibre Diameter, a representative sample must be obtained. A core sample is taken from each bale in a sale lot under the supervision of an AWTA sampling officer. The bale weight is recorded at the time of sampling.

Yield is the amount of clean fibre, at a standard moisture content, that is expected to be produced when a parcel of raw wool is processed. The yield may be expressed as a clean mass in kilograms and as a percentage of the mass of raw wool prior to processing.

|

Yield is calculated by first determining the amount of clean dry fibre (Wool Base) and Vegetable Matter Base (VM).The amount of residual components that remain are determined and subtracted in order to obtain the Wool Base. These residual components are:

|

Once all the residual components have been measured, the Wool Base is calculated. The Wool Base is calculated by expressing the weight of wool with the impurities removed as a percentage of the original scoured wool weight. The Wool Base is then used to calculate various commercial yields.

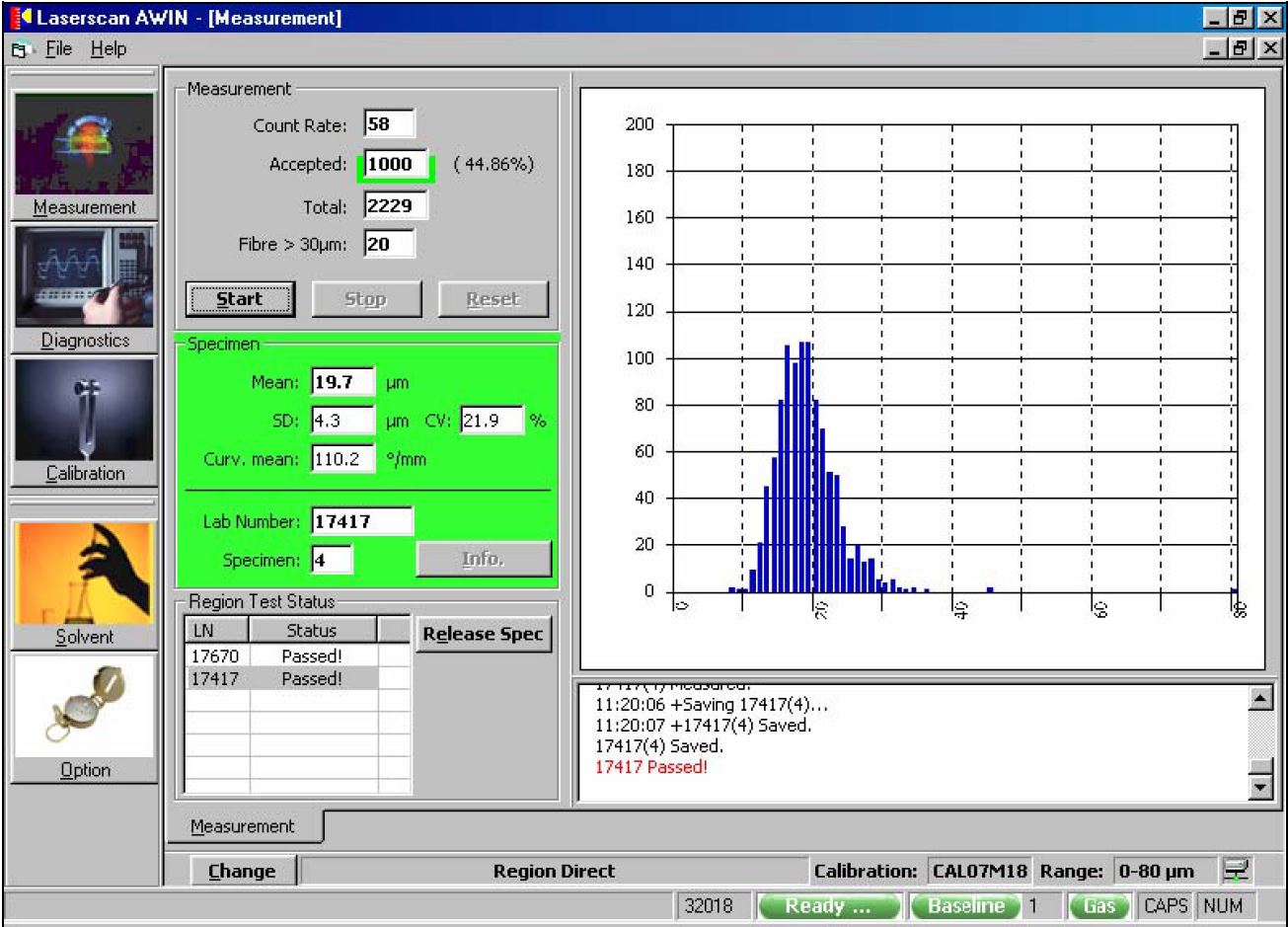

| Fibre Diameter is the thickness of individual wool fibres, its measurment is used to determine the end-use of the wool. Fibre diameter is measured using a Lasercan instrument, results are reported in microns. A conditioned sample of scoured wool is mini-cored to produce a sub-sample consisting of snippets of fibre. The snippets are dropped into a bowl containing water and mixed before the water containing the suspended snippets is released and flows in tubing through a measurement cell containing an array of lasers. As the snippets move through the laser beams in the measurement cell the size of the shadow cast by the individual fibres is recorded. |  |

For a standard test samples are measured on four separate Laserscan instruments and 1,000 individual fibres are measured on each machine. The combined results from 4,000 snippets, are used to calculate the Mean Fibre Diameter. Measurements are made on individual fibres, as a result a distribution of the diameters are accumulated and the Coefficient of Variation of Diameter (CVD) calculated. In addition, the final certificate will show the Fibre Curvature of the fibres in the sample and the Comfort Factor of the sample.