Raw Wool Laboratory Equipment

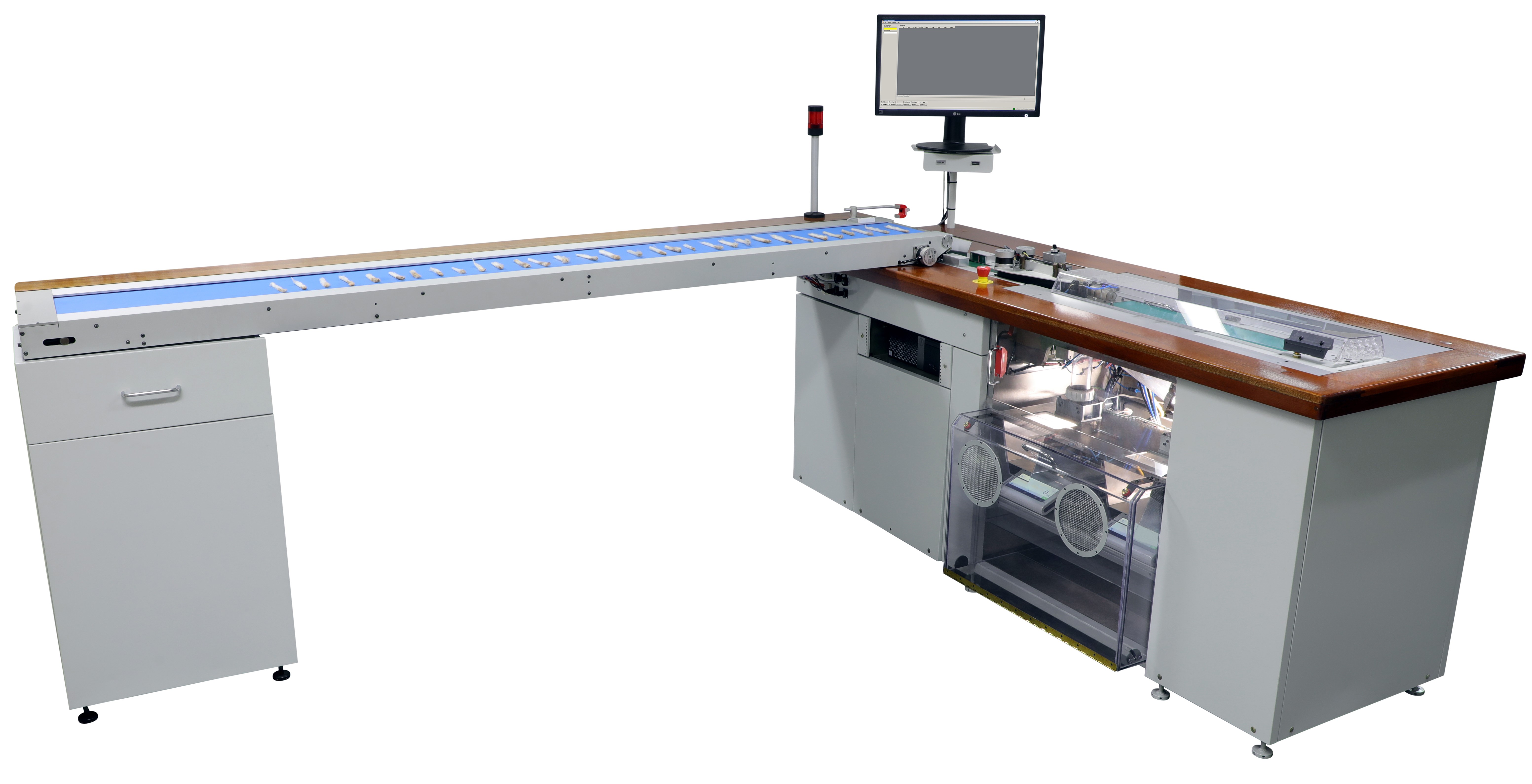

The NextGen Laserscan

The measurement of wool fibre diameter can be conducted through four distinct methods as delineated by the International Wool Textile Organisation (IWTO). AWTA Ltd employes the IWTO-12 Laserscan fibre diameter analyser method for fibre diameter certification and fleece measurement services.

In 1972, CSIRO initiated the development of the first Laserscan, establishing the foundation and obtaining approval for the method from the IWTO. Subsequently, in 1996, AWTA Ltd acquired the rights to manufecture and sell the Laserscan and continued its further development.

Introduced in 2014, the NextGen Laserscan has swiftly established itself as a cutting-edge technology in the field. Its global clientele spans a diverse range of end users, encompassing universities, mills, government facilities, and more. The market reception of the NextGen Laserscan has been exceptional, attesting to its innovative features and precision in measuring wool fiber diameter. With its widespread adoption, it has become an indispensable tool for various industries and research institutions, setting new standards in fiber measurement and analysis.

"The NextGen Laserscan - The precise measurement of wool fibre diameter"

"The NextGen Laserscan - The precise measurement of wool fibre diameter"

How does it work?

The Wool Industry has chosen to characterise Fibre Diameter in relation to the average thickness or width of a two-dimensional projected image composed of numerous fibre snippets. In the accompanying figure1, microsopic fibre cross-sections are depicted. The non-uniform geometry complicates the definition of Mean Fibre Diameter (MFD), rendering it a more intricate task than it many initially apear.

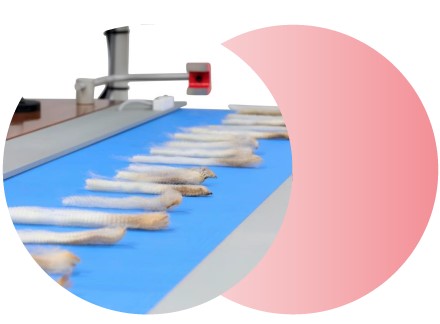

The fibre snippets are very short pieces of fibre, typically around 2mm long, which have been cut at random positions along the length of the fibre. The precise mechanisam for doing this usually involves using a Minicore.

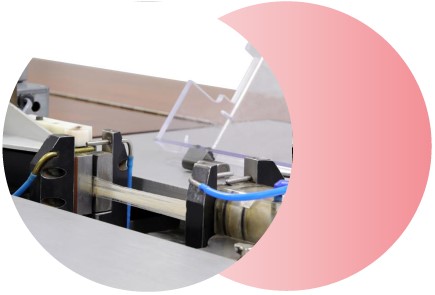

The NextGen Laserscan works by mixing fibre snippets with water and a neutral detergent called transporation fluid. The mixture then flows through a measurement cell, where the shadow cast by the wool fibre snippet in a laser beam is utilised to determine its diameter.

Technical Information

The AWTA NextGen Laserscan instrument meets the test standards of the International Wool Textile Organisation standard IWTO-12-2012.

The NextGen Laserscan Model is a cutting edge solution that revolutionises precision measrements with its advanced features and user-frendly design. It boasts seamlessly intergrated electronics, ensuring optimal performance and reliability. Navigating through intricate measurements is a breeze with the simple and easy-to-use user interface, thanks to Laserscan AWIN II software, empowering users of all skill levels. The temperature-controlled cabinet guarantees stable operating conditions, enhancing the accuracy and consistency of your results. Embrace efficiency with the full automatic process, streamlining your workflow and minimising manual intervention. The NextGen Laserscan goes beyond conventional standards by employing a water based transporation fluid, not only promoting environmental sustainability but also contributing to a clean and effcient operation.

Lastest Video

Download Content

| LINK TO TECHNICAL MATERIAL |

ATLAS - Staple Length & Strength Measurement

One of the most important characteristics that determines the value of combing wool is the average fibre length which will be achieved after processing. This length is known as Hauteur. Research has shown that Hauteur is closely correlated to the staple length and staple strength of the greasy wool measured prior to processing.

Prior to the measurement of Staple Length & Strength three levels of sampling need occur:

- Grab sampling from the bales of wool in the lot

- Tuft sampling from the grab sample

- Staple preparation of the tufts

Once the above steps are complete, the staple sof greasy wool are measured on an instrument called the Automatic Tester of Length and Strength (ATLAS). This instrument measures:

- The mean Staple Length of the staples (mm)

- Coefficient of Variation of Staple Length (CV%)

- Mean Staple Strength (N/ktex)

- Distribution of Position of Break (POB%)

How does it work?

Length and Strength is measured using an instrument called the Automatic Tester of Length and Strength (ATLAS).

Length is measured by conveying the staple; tip first, through a vertical array of eight light beams and then electronically measuring the distance the conveyor moved while the light beams were interrupted by the staple. All staples are measured for Length regardless of the staple dimensions. Length is measured in millimetres. The IWTO standard requires that a minimum of 55 staples are measured for Length to produce a certified result.

After Length measurement, the staple is picked up by two rubber belts which feed it through to a jaw which grips the tip of the staple. A jaw then moves away until the base of the staple is clear of the rubber belts. The base jaw then grips the base of the staple. The tip jaw moves away and the staple is broken in two. The peak force required to break the staple is measured in Newtons (N) by a force transducer attached to the stationary (base) jaw.

|

|

On its own, this information is of little value since the staples that are measured vary in thickness. All things being equal, thick staples require a greater force to break than thin staples. Therefore, the force required to break a staple must be related to staple thickness before it can be used more meaningfully.

Staple thickness is determined from the weight of the staple and the Length of the staple. That is, the more grams of weight per millimetre of Length, the thicker the staple. Staple thickness is measured in kilotex (ktex). The total Newtons of force is divided by the number of kilotex to give a Strength value per unit of thickness (N/ktex). This figure is known as the greasy Staple Strength because it was derived from the greasy staple weight. This is then converted to a measure of clean Staple Strength using the Wool Base and VM Base information.

Technical Information?

The Atlas P3 measures the Staple Length and Strength of a set of wool staples in accordance with IWTO-30-2007 standards.

Individual wool staples are placed on a belt, which conveys them to the length-measuring section. Length is determined using a light array that senses the start and end of each staple. The staple is then transported to the strength section where jaws grip each end of the staple. The staple is broken, and the force required to break it is recorded. The broken staple pieces are then independently weighed to determine the position of the break in the staple.

From this information, the Average Staple Length (mm), Coefficient of Variation of Staple Length (%), Average Staple Strength (N/ktex), and Position of Staple Break (%) are all determined for the set of staples.

Latest Video

Download Content

| LINK TO TECHNICAL MATERIAL |

ATLAS - Staple Length & Strength

Additional Equipment & Techincal Information

Download Brochures

Centrifuge - 1500C

Dryer - 1250MHD

Dryer - 1250VMD

Scour - AWS3