Raw Wool Laboratory Equipment

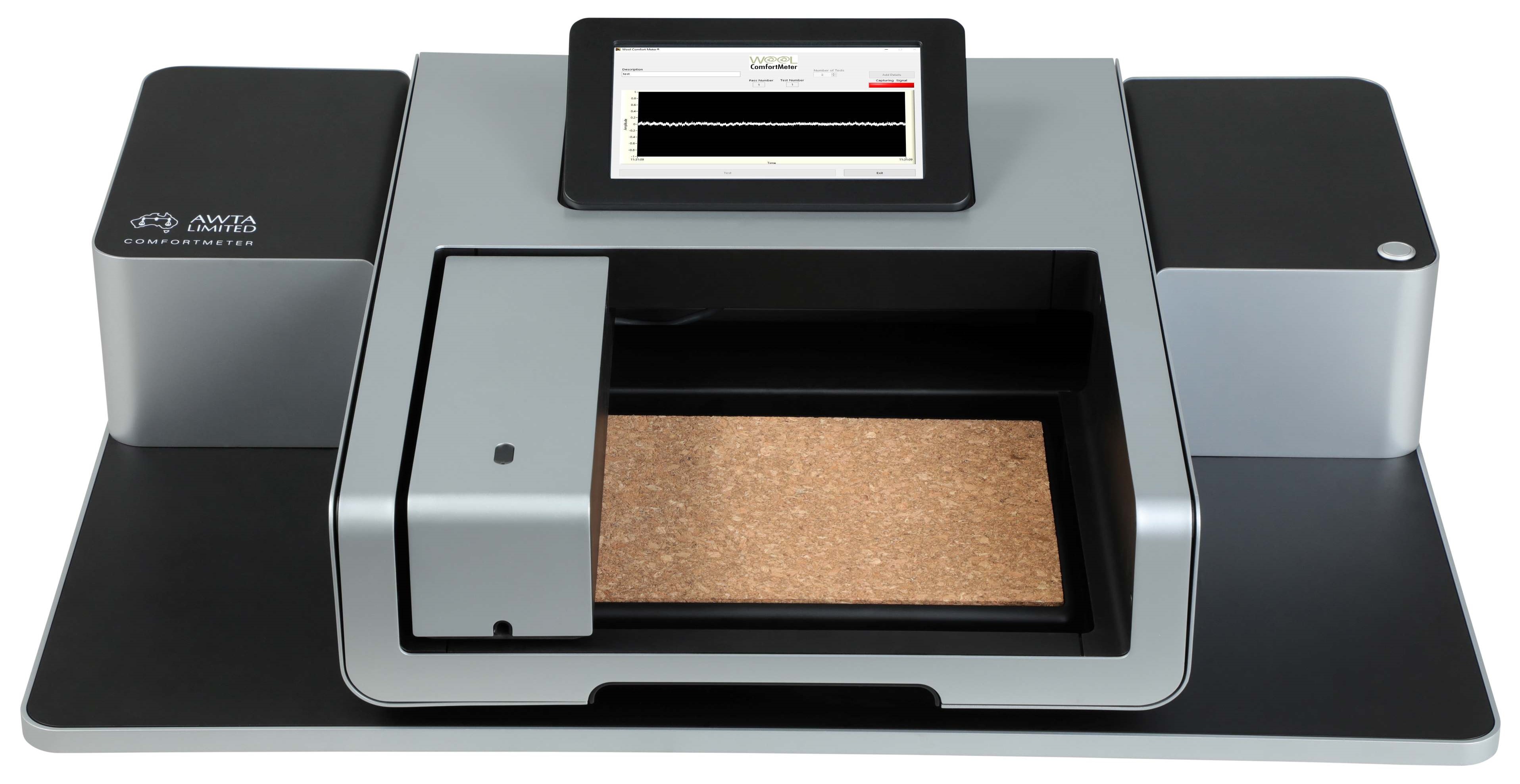

The NextGen Laserscan

The measurement of wool fibre diameter can be conducted through four distinct methods as delineated by the International Wool Textile Organisation (IWTO). AWTA Ltd employes the IWTO-12 Laserscan fibre diameter analyser method for fibre diameter certification and fleece measurement services.

In 1972, CSIRO initiated the development of the first Laserscan, establishing the foundation and obtaining approval for the method from the IWTO. Subsequently, in 1996, AWTA Ltd acquired the rights to manufecture and sell the Laserscan and continued its further development.

Introduced in 2014, the NextGen Laserscan has swiftly established itself as a cutting-edge technology in the field. Its global clientele spans a diverse range of end users, encompassing universities, mills, government facilities, and more. The market reception of the NextGen Laserscan has been exceptional, attesting to its innovative features and precision in measuring wool fiber diameter. With its widespread adoption, it has become an indispensable tool for various industries and research institutions, setting new standards in fiber measurement and analysis.

"The NextGen Laserscan - The precise measurement of wool fibre diameter"

"The NextGen Laserscan - The precise measurement of wool fibre diameter"

How does it work?

The Wool Industry has chosen to characterise Fibre Diameter in relation to the average thickness or width of a two-dimensional projected image composed of numerous fibre snippets. In the accompanying figure1, microsopic fibre cross-sections are depicted. The non-uniform geometry complicates the definition of Mean Fibre Diameter (MFD), rendering it a more intricate task than it many initially apear.

The fibre snippets are very short pieces of fibre, typically around 2mm long, which have been cut at random positions along the length of the fibre. The precise mechanisam for doing this usually involves using a Minicore.

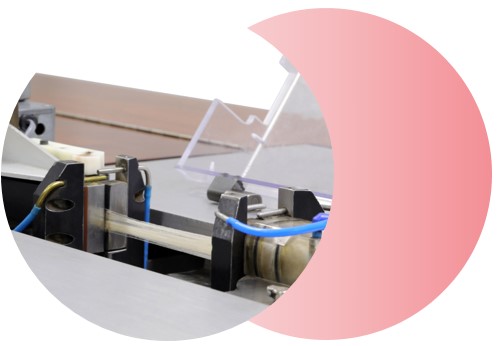

The NextGen Laserscan works by mixing fibre snippets with water and a neutral detergent called transporation fluid. The mixture then flows through a measurement cell, where the shadow cast by the wool fibre snippet in a laser beam is utilised to determine its diameter.

Technical Information

The AWTA NextGen Laserscan instrument meets the test standards of the International Wool Textile Organisation standard IWTO-12-2012.

The NextGen Laserscan Model is a cutting edge solution that revolutionises precision measrements with its advanced features and user-frendly design. It boasts seamlessly intergrated electronics, ensuring optimal performance and reliability. Navigating through intricate measurements is a breeze with the simple and easy-to-use user interface, thanks to Laserscan AWIN II software, empowering users of all skill levels. The temperature-controlled cabinet guarantees stable operating conditions, enhancing the accuracy and consistency of your results. Embrace efficiency with the full automatic process, streamlining your workflow and minimising manual intervention. The NextGen Laserscan goes beyond conventional standards by employing a water based transporation fluid, not only promoting environmental sustainability but also contributing to a clean and effcient operation.

Lastest Video

Download Content

| LINK TO TECHNICAL MATERIAL |

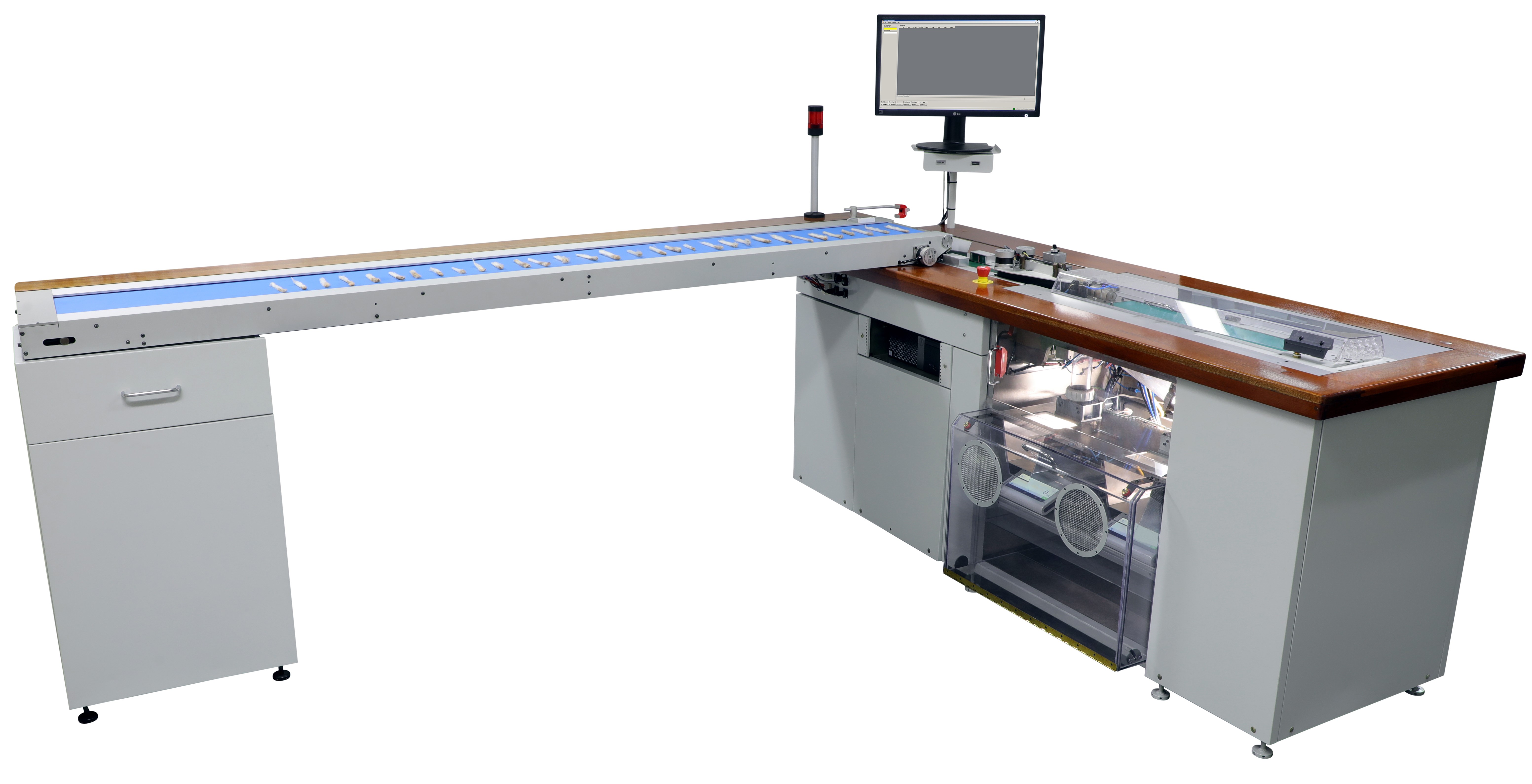

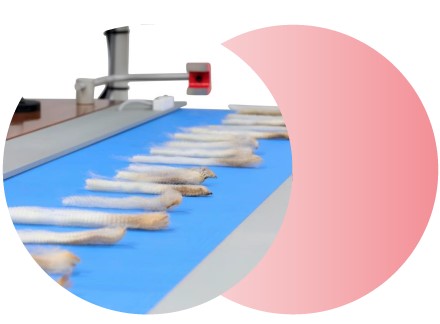

ATLAS - Staple Length & Strength Measurement

One of the most important characteristics that determines the value of combing wool is the average fibre length which will be achieved after processing. This length is known as Hauteur. Research has shown that Hauteur is closely correlated to the staple length and staple strength of the greasy wool measured prior to processing.

Prior to the measurement of Staple Length & Strength three levels of sampling need occur:

- Grab sampling from the bales of wool in the lot

- Tuft sampling from the grab sample

- Staple preparation of the tufts

Once the above steps are complete, the staple sof greasy wool are measured on an instrument called the Automatic Tester of Length and Strength (ATLAS). This instrument measures:

- The mean Staple Length of the staples (mm)

- Coefficient of Variation of Staple Length (CV%)

- Mean Staple Strength (N/ktex)

- Distribution of Position of Break (POB%)

How does it work?

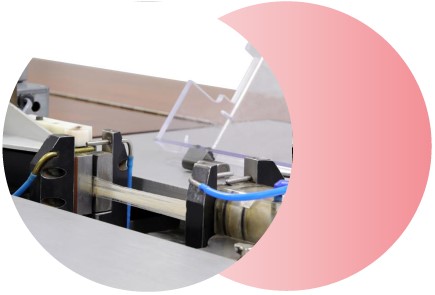

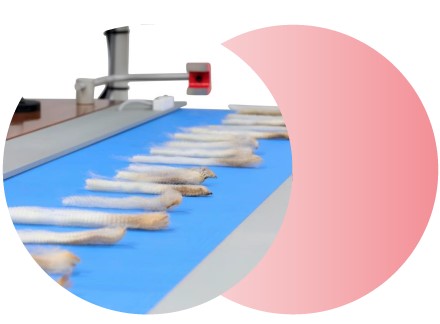

Length and Strength is measured using an instrument called the Automatic Tester of Length and Strength (ATLAS).

Length is measured by conveying the staple; tip first, through a vertical array of eight light beams and then electronically measuring the distance the conveyor moved while the light beams were interrupted by the staple. All staples are measured for Length regardless of the staple dimensions. Length is measured in millimetres. The IWTO standard requires that a minimum of 55 staples are measured for Length to produce a certified result.

After Length measurement, the staple is picked up by two rubber belts which feed it through to a jaw which grips the tip of the staple. A jaw then moves away until the base of the staple is clear of the rubber belts. The base jaw then grips the base of the staple. The tip jaw moves away and the staple is broken in two. The peak force required to break the staple is measured in Newtons (N) by a force transducer attached to the stationary (base) jaw.

|

|

On its own, this information is of little value since the staples that are measured vary in thickness. All things being equal, thick staples require a greater force to break than thin staples. Therefore, the force required to break a staple must be related to staple thickness before it can be used more meaningfully.

Staple thickness is determined from the weight of the staple and the Length of the staple. That is, the more grams of weight per millimetre of Length, the thicker the staple. Staple thickness is measured in kilotex (ktex). The total Newtons of force is divided by the number of kilotex to give a Strength value per unit of thickness (N/ktex). This figure is known as the greasy Staple Strength because it was derived from the greasy staple weight. This is then converted to a measure of clean Staple Strength using the Wool Base and VM Base information.

Technical Information?

The Atlas P3 measures the Staple Length and Strength of a set of wool staples in accordance with IWTO-30-2007 standards.

Individual wool staples are placed on a belt, which conveys them to the length-measuring section. Length is determined using a light array that senses the start and end of each staple. The staple is then transported to the strength section where jaws grip each end of the staple. The staple is broken, and the force required to break it is recorded. The broken staple pieces are then independently weighed to determine the position of the break in the staple.

From this information, the Average Staple Length (mm), Coefficient of Variation of Staple Length (%), Average Staple Strength (N/ktex), and Position of Staple Break (%) are all determined for the set of staples.

Latest Video

Download Content

| LINK TO TECHNICAL MATERIAL |

ATLAS - Staple Length & Strength

Additional Equipment & Techincal Information

Download Brochures

Centrifuge - 1500C

Dryer - 1250MHD

Dryer - 1250VMD

Scour - AWS3

Contact Us - Direct Link

TOPMARK Benchmarking

TOPMARK is a free benchmarking service for processing mills and topmakers around the world. Independent trials have established there is a strong correlation between the predictive formulae used in this service and the processing performance of wool mills. This relationship is used to compare individual mill batches against the overall pool of data and identify areas where improvements can be made.

|

Participation is very simple, with mills providing AWTA with greasy wool test information on their batches as well as their own processing test data. We collate the data from all participating mills and determine ‘benchmarks’ for all the major processing results. These benchmarks will allow one mill to confidentially compare its performance against the average of all the other mills participating in this program. Confidential reports are provided regularly to mills detailing their performance against key characteristics such as Hauteur, Romaine, Top & Noil Yield, and Core/Comb Fibre Diameter. |

Participation in TOPMARK is free. Simply contact us and agree to provide greasy wool and top test results on processing batches and these will be entered into a confidential database from which the processing performance of each mill can be compared. A standard form has been created to assist mills in submitting the required data.

What are the benefits of Benchmarking?

Benchmarking is the collection of performance information that allows comparisons to be made between organisations. It is typically designed to answer the question: “What are the most important performance yardsticks and where do we rank, compared with others in our industry?” It is generally recognised that, when used appropriately, benchmarking is one of the most effective tools for bringing about improvements in performance.

Some of the typical benefits are as follows:

- Allows a wide range of performance indicators to be studied

- Protects confidentiality of all partners

- Allows comparisons with competitors to be made and allows identifi cation of best practice

- Allows performance shortfalls to be clearly seen and assists in identifying priorities for improvement

- Encourages participants to seek fresh approaches to bring about improvements in performance

TOPMARK™ is a registered trademark of the Australian Wool Testing Authority

Find out more:

Research and Development

Research & Development plays a major part in the development of AWTA Raw Wool. Based in Melbourne, the Research & Engineering group forms the largest wool measurement and engineering research group in the wool industry.

Work conducted by the group falls into the following areas:

- Fundamental research to develop an understanding of the underlining physics of specific measurement systems

- Development of test methods, standards & regulations

- Development, design & manufacture of testing equipment for in-house use & sale

- Industry projects & collaborations

- General wool metrology & analysis

- TopMark - Mill Benchmarking

AWTA researchers are available to conduct and manage research projects under contract or in partnership with others. The Research teams expertise is extensive and covers the following broad areas:

- Wool measurement science

- Textile physics & engineering

- Experimental design & statistical analysis

- Near Infra-Red Spectroscopy

- Management of research projects

Find out more:

Fact Sheet - Research Metrology![]()

Equipment Manufacturing

AWTA Raw Wool manufactures or subcontracts the manufacturing of most of the equipment that is used in its laboratories. Much of this is specialised equipment that cannot be obtained from other sources.

|

AWTA is the largest supplier of wool testing equipment in the world, and has delivered equipment into Europe, Asia, New Zealand, South Africa and South America. In particular, AWTA is licensed to manufacture the NextGen Laserscan used to determine the fibre fineness characteristics of wool, and the ATLAS instruments, used for determining Staple Length & Strength. Manufactures of Raw Wool testing equipment: |

|

|

|

AWTA has a number of machines available for sale on a built to order basis. Occasionally a limited number of second hand machines become available and may be sold as refurbished models or “as-is”.

Download Content & Brochures

Electronic Services

AWTA offers a wide range of online and electronic services including:

- Electronic Data Interchange (EDI)

- TOPMARKTM Benchmarking

- Combined Certificates & Objectively Matched Lots (OMLs)

- Electronic Certificates including Chinese translations

- Online Certificate Verification

Electronic Data Exchange (EDI)

AWTA has been at the forefront of the development and adoption of Electronic Data Interchange (EDI) systems within the wool industry through membership of the Wool Industry Electronic Data Processing Users Group (WIEDPUG).

This industry body is responsible for implementing data communication standards within the wool industry, with which all AWTA EDI services comply. This covers both the sending and receiving of test data, sale lot information and our EDI mailbox service, as well as many other transactions that occur in the trade of wool.

The electronic distribution of data is an integral part of AWTA’s services. Through our EDI facilities, AWTA provide electronic data for virtually every test we undertake. Customers can improve service turnaround and reduce testing costs by transmitting sale lot and bale weight data to AWTA as part of our standard core testing service.

Find out more:

Fact Sheet - Electronic Data Interchange![]()

EDI Service - Update Notice - July 2010![]()

TOPMARK - Global Benchmarking for Topmakers

TOPMARK is a free benchmarking service for processing mills and topmakers around the world. Independent trials have established there is a strong correlation between the predictive formulae used in this service and the processing performance of wool mills. This relationship is used to compare individual mill batches against the overall pool of data and identify areas where improvements can be made.

|

Participation is very simple, with mills providing AWTA with greasy wool test information on their batches as well as their own processing test data. We collate the data from all participating mills and determine ‘benchmarks’ for all the major processing results. These benchmarks will allow one mill to confidentially compare its performance against the average of all the other mills participating in this program. Confidential reports are provided regularly to mills detailing their performance against key characteristics such as Hauteur, Romaine, Top & Noil Yield, and Core/Comb Fibre Diameter. |

Participation in TOPMARK is free. Simply contact us and agree to provide greasy wool and top test results on processing batches and these will be entered into a confidential database from which the processing performance of each mill can be compared. A standard form has been created to assist mills in submitting the required data.

What are the benefits of Benchmarking?

Benchmarking is the collection of performance information that allows comparisons to be made between organisations. It is typically designed to answer the question: “What are the most important performance yardsticks and where do we rank, compared with others in our industry?” It is generally recognised that, when used appropriately, benchmarking is one of the most effective tools for bringing about improvements in performance.

Some of the typical benefits are as follows:

- Allows a wide range of performance indicators to be studied

- Protects confidentiality of all partners

- Allows comparisons with competitors to be made and allows identifi cation of best practice

- Allows performance shortfalls to be clearly seen and assists in identifying priorities for improvement

- Encourages participants to seek fresh approaches to bring about improvements in performance

TOPMARK™ is a registered trademark of the Australian Wool Testing Authority

Find out more:

TOPMARK Consignment Nomination Form![]()

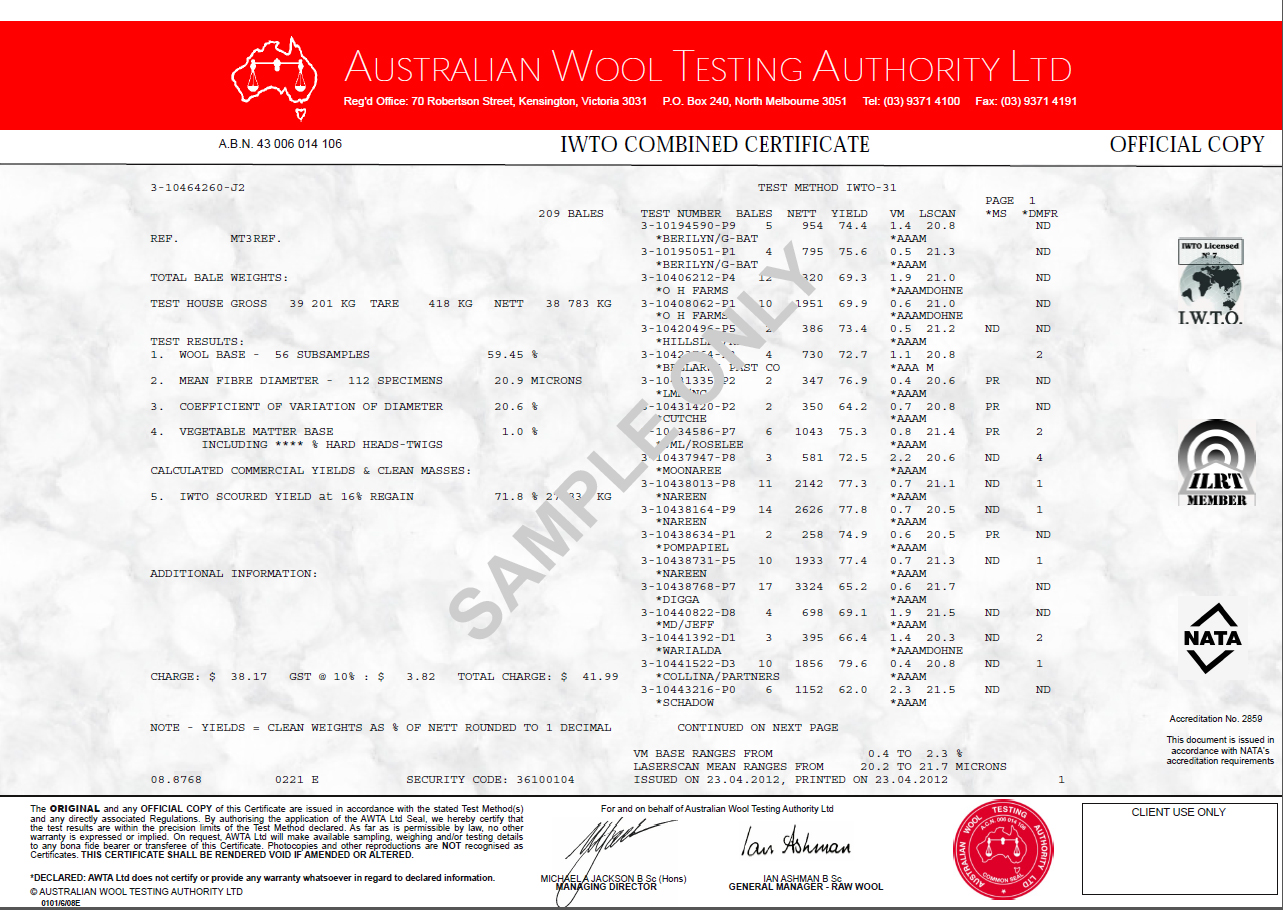

IWTO Combined Certificates & OMLs

Wool Exporters and processors require certificates that show the overall measurement specifications for consignments they are delivering to mills and banks which issue letters of credit. These consignments often consist of numerous sale lots purchased according to these specifications. As it is not cost effective for the individual sale lots to be resampled and measured again as a single test, AWTA provides a service where the tests of individual sale lots can be arithmetically combined to show the overall average measurements. These IWTO Combined Certificates are widely recognised and trusted throughout the wool supply chain. Similarly, the same process can be used to produce Objectively Matched Lots, however the combination of lots is restricted by minimum and maximum measurement ranges.

Combination Calculations

Fact sheets illustrating the procedures defined in IWTO-31 for combining Mean Fibre Diameter, CVD and Fibre Diameter Distributions are available for download. The IWTO-31 standard establishes the combination procedures for all certifiable parameters and other parameters that are provided for information.

These include:

|

|

Other rules and calculations that govern the creation of Objectively Matched Lots (OMLs) are provided in the Fact sheet below.

Find out more:

Combining Mean Fibre Diameters & CVDs![]()

Objectively Matched Lot Request![]()

Requirements for Combining OMLs![]()

Sample Spreadsheets

The spread sheets provided below show all Combination calculations, as well as the procedure for Combinations by Subtraction. The Combinations by Subtraction spread sheet is used when a small proportion (less than 5% by weight) is removed from a delivery. The removed component is retested and subtracted from the original combination.

Find out more:

Electronic Certificates (eCerts)

AWTA produces electronic Test Certificates and Guidance Reports as part of our standard services. These can be emailed in PDF format direct to the requestor as soon as testing is complete. The format is identical to that of the printed documents and includes multiple copies. Paper Certificates are still available by request but printing them will incur an additional fee. IWTO Combined Certificates are also available translated into Chinese.

AWTA has introduced a number of security measures that protect the integrity of our Electronic Certificates. One such feature is the use VeriSign digital signatures to secure the PDF files prior to distribution from our server. If the document is changed in anyway, then the signature becomes invalid. If the signature is intact, you will see the following banner in the Adobe Acrobat Reader window.

![]()

Recipients of any Electronic Certificates should setup their MS Windows Certificate store so that Acrobat Reader can check the digital signature is valid.

Find out more:

Electronic Certificates - Chinese![]()

Online Certificate Verification

The Online Verification system allows holders of AWTA Test Certificates to request additional PDF copies by simply entering the certificate number, some security information and an email address into an online form. It has been provided so that people who have Certificates in their possession can check that they are legitimate. It is not designed to allow Certificates to be reproduced by those that do now own them.

Simply go to our website and enter the full Certificate number, the security code (which is displayed at the bottom of the test certificate) and the email address that you want it sent to and press the “Verify Certificate Details” button. A PDF file is then sent automatically to the nominated email address. All entries and updates that take place on this web page are logged.

The Online Verification system was introduced to allow legitimate owners of AWTA’s Test Certificates or Reports to confirm the details of documents they have in their possession. It is not designed to allow Certificates to be reproduced or distributed by those that do not own them. Even contacting AWTA directly to ask for an Electronic Certificate may require the requestor to establish that they are the bona fide owner.

|

|

Find out more:

Online Verification of Certficates![]()

Online Verification of Certificates - Chinese![]()

More Articles ...

Subcategories

- Raw Wool Testing

-

Electronic Services

AWTA offers a wide range of online and electronic services including:

- Electronic Data Interchange (EDI)

- TOPMARKTM Benchmarking

- Combined Certificates & Objectively Matched Lots (OMLs)

- Electronic Certificates including Chinese translations

- Online Certificate Verification